We are central to produce core rolling mills components from welded structure to mechanically manufactured parts and all components will be pre-assembled in our own workshops, to ensure top final products under our own quality control.Our solutions are distinctively tailored to customers’ expectations. We are dedicated to move forward to offer reality-and-concept-combined(RCC) solution and detailed-and-precise-manufacturing(DPM) approach, to ensure you get ultimate reliable quality and high-performance products. |

14,000 m2 devoted to production and assembly

Ranks among the most reputed rolling mill company in China

Engineering and production under one roof to ensure efficient order processing

Production of core rolling mill components from welded structures to mechanically manufactured to ensure top final products under our quality control

Location benefits from its traffic-favorable place for heavy load transports: Beside the national road 312 and very close to Shanghai Port for worldwide ocean freight

Under one roof

Successfully developed modernized MKW 8-HI precise rolling mill under research and development Continuous interactions of ideas between engineering, production and mill usage for optimization of our products

Function is optimized based on customer-oriented communication of requirement

Vision: INTEGRITY, BEYOND, DETAIL, CUSTOMER-ORIENTIED

Mission: Higher quality, Increased productivity, lower operation cost, lower maintenance

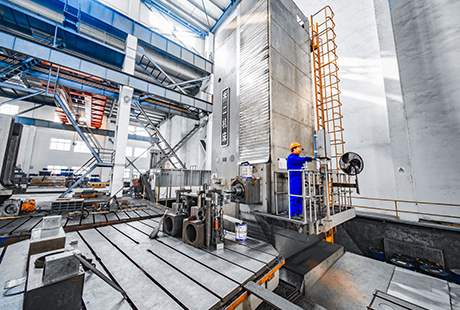

Turning, shaping, drilling, grinding, milling

50+ machining facilities, including boring milling, drilling, shaping, grinding machines and etc.

Crane capacity: 130 t

Single machining capacity: up to 120 t

Raw machining area, precision machining area, welding area, and assembly area

Precision machining equipment is CNC controlled for higher surface quality and high accuracy

CNC lathes

Important to ensure machine stability

CNC flame cutting machine or CNC wire-cut electric discharge machines applied upon different processing requirement

Welded structure is being emphasized as it must withstand mill’s extreme static and dynamic stresses

Quenching and heat treatment is processed for each piece of welded components

Top welding quality by guarantee of our qualified employees who are professional in welding

Surface treatment conducted

Extending service life

Superior upgraded material management

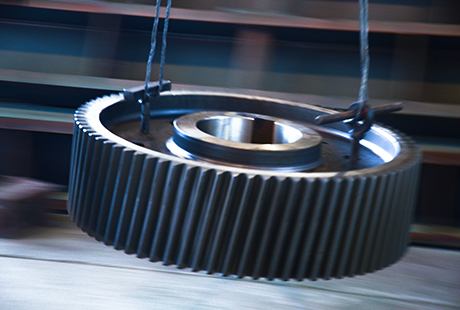

Under treatment of carburizing, quenching and tempering ensure better wearing resistance and higher hardness, reducing maintenance ratio

Tooth grind level as high as grade 6

Greater stability and much lower noise inside gearbox

All our gear parts feature high surface quality, especially on the tooth

Lifting capacity: weight up to 130 t, lifting height up to 15 m

Weight: up to 120 t

Our team pre-assemble or fully assemble products at workshop based on order specification

Test performed for higher accuracy during pre-assembly:i.e. mobile 3D laser track for all housing, bearing house and core components

Surface treatment for components or as requirement, i.e. painting and preservation as well as preparation for shipment

Higher than the best

The most reputed suppliers among industries to cooperate with

For suppliers, we apply our own standards which go far beyond the usual norms (one of our suppliers comments that NANBAO’s requirement on specification is the strictest among their customers)

Raw material is only adopted when material analysis report as well as flaw detection report meet our requirement

Selecting suppliers cooperating up to now are qualified by a long time usage and customers’ recognition

i.e. Reputed-brand cylinders are used. Cylinder’s performance makes an important role in mill’s long-time operation. Situations as oil splitting or emulsion tank being polluted will never happen

High quality is our hallmark

FARO’s Mobile 3D laser track for all housing, bearing house and core components to ensure high machining accuracy

We apply our own standards which go far beyond the usual norms

High machining accuracy is the key to mill’s better performance in rolling stability, rolling accuracy, strip shape, low maintenance as well as mill service life so as to simultaneously increase productivity and lower overall operation cost

Professional and efficient

Our installation team are experts in site installation

Installation work once receives customers’ accomplishment

Respond at any time and guarantee to deal with situation at site within 24 hours, upon receiving request

Lifelong maintenance service even beyond warranty period

Operator training service is available based on your request

First and foremost, our workshop is mainly produce core products and components from NANBAO product range. But it is also usual for us to accept external production orders in the following fields:

Mechanical production

Welding production

Assembly

You are free to contact with us and ask questions you may have, or during a personal meeting if you wish.

Typical mechanical production covers separate parts of rolling mill, housing, frames, gears, shafts, and etc. Our core mechanical manufacturing includes raw machining and precise machining of turning, shaping, drilling, grinding, milling. Latest-generation machines enable us to process complex components in a great range of types. Top quality in single piece or volume manufacturing is guaranteed. You are free to contact with us and ask questions you may have, or during a personal meeting id you wish.

Typical welding includes individual welded structure or complete work required for assembly. We are able to take care of various material management and treatment as required including heat treatment, quenching, sand blasting, coating and etc. NANBAO ensures top welding quality by employees who are professional in welding. High-tech welding capability and management ensures high efficiency welding manufacturing. You are free to contact with us and ask questions you may have, or during a personal meeting id you wish.

Lifting capacity: weight up to 130 t, lifting height up to 15 m Weight: up to 120 t Our team pre-assemble or fully assemble products at workshop based on order specification Test performed for higher accuracy during pre-assembly:i.e. mobile 3D laser track for all housing, bearing house and core components Surface treatment for components or as requirement, i.e. painting and preservation as well as preparation for shipment

Contact Us

Contact Us