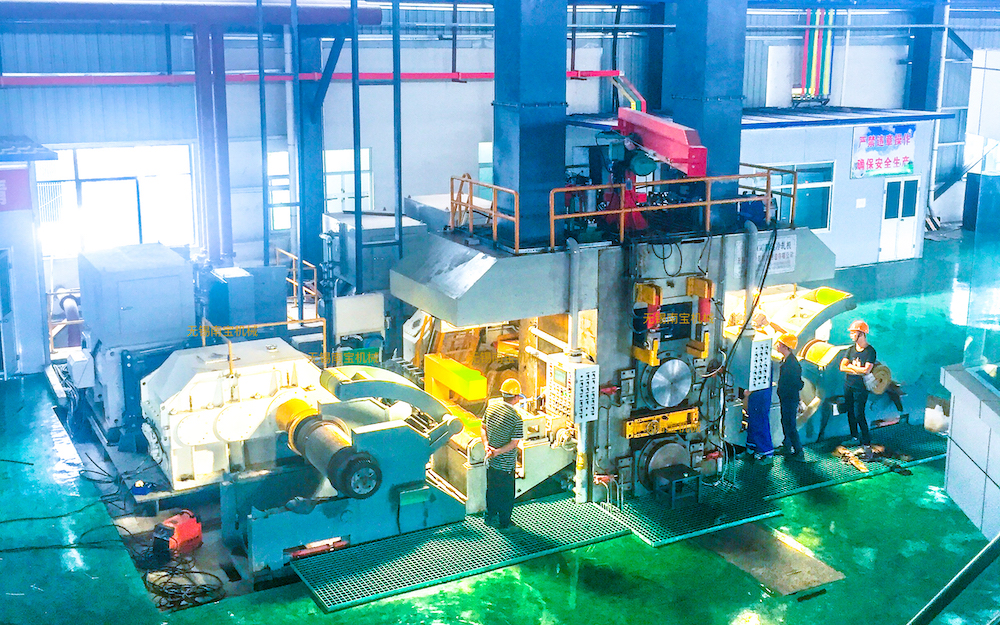

A cooperation with Lianyungang Huale Alloy represents the further progress of Nanbao in the field of cold rolling mill technology. Four sets of 850mm AGC high-speed cold rolling equipment have achieved a combination of higher-speed rolling and flexible production.

The new high-speed cold-rolling line's design concept simultaneously meets the high-volume and high-quality production requirements for private steel mills, as well as the production flexibility of "one machine and multiple uses": according to different materials and different rolling requirements, the low-speed gear and high-speed gear can be flexibly switched. To meet the rolling of various alloy materials, achieving the combination of rough rolling and finishing rolling.

The rolling mill was commissioned and completed on time. During the test run, the first strip was produced at a high-speed rolling speed of 400m / min, and the tolerances of the finished product were strict. It again demonstrated the efficient cooperation between Wuxi Nanbao and Lianyungang Huale.

Lianyungang Huale Alloy is one of the large-scale steel mills in China, and it is also the first private enterprise of full-process stainless steel production in Jiangsu Province. Production of various alloys including nickel alloys, chromium alloys, stainless steel, etc. The monthly production capacity of stainless steel in the first-phase project is expected to be 18,000 tons.

Wuxi Nanbao has won the recognition of our customers with its precise design, excellent equipment and precise product quality for the long run.

Contact Us

Contact Us