Steel product of top-quality and high diversity tends to be new market demand. To meet the increasing new market demand, the ability to manufacture flexible and high quality becomes more and more important. Electrical and automation solutions, as one of the most efficient solution for plants requirement, has a growing demand.

We offer the complete electrical and automation solutions for cold rolling mill, including basic automation, motor and drive system, processing control system, power quality control. Premium suppliers for electrics and automation system are relied on to meet diverse requirements of products you need.

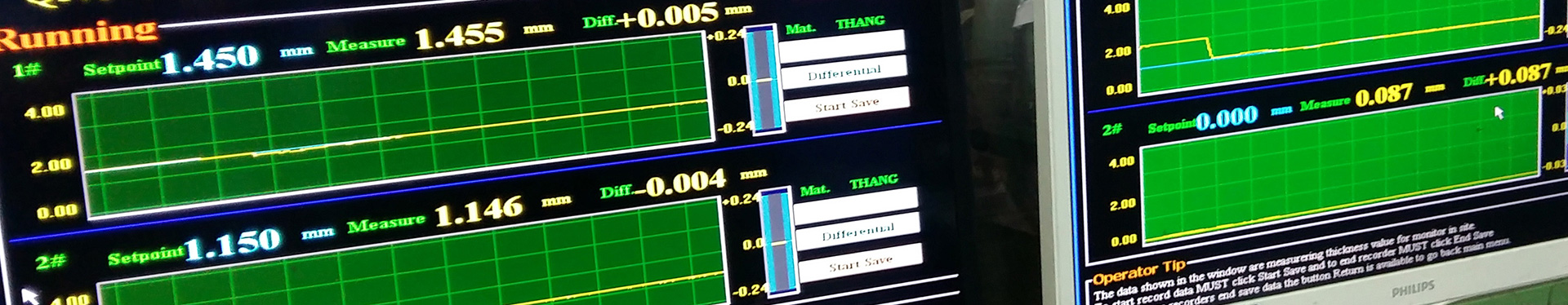

We Hydraulic AGC gauge control system help plant achieve high rolling precision, which means a solution carter to increasing market demand for top quality product and to make plant stay competitive in the future.

In order to guarantee thickness precision and good shape of steel strip, the system is provided with hydraulic Automatic Gauge Control (AGC), Constant Roll-gap Control (APC), Constant Pressure Control (AFC), thickness supervision, and thickness pre-control. For thin products, tension control and other functions may also be used. Standard functions like reliability, easy operation, self protection as well as acquisition of rolling processing database. Every time before rolling different materials, corresponding rolling process database can be called to set. After the system is applied, the thickness precision of cold rolling will reach: 0.15±0.003 mm and 0.3±0.006 mm

AGC function of thickness, monitoring and pre-control

Lift the roller quickly and calibration of the rolling mill

Manual and automatic setting of roll-gap

Overload protection and alarm display function

The function to collect data, record, display of parameters during the rolling process

The function to record fault

Great HMI and dialogue function.

Remove the thickness deviation of strip due to water mark or temperature difference between strip head and tail

Remove the thickness deviation of strip due to tension lost at the tail.

Reduce the time set for roller change and roll-gap, improving operation efficiency

Gap accuracy: than 0.001mm

Control accuracy of strip thickness: ±1.5~3%h

System response time: 30-50 m/s

A lot of harmonics appear in production lines with rectifying installation in cold rolling, resulting in fast attenuation of motor cable insulation, increase of loss, decrease of output efficiency, and loss of transformer capacity. When the harmonics influenced waveform distortion of input power supply exceeds national limited value, the power consumption rate increases or even power breakdown. Sudden power breakdown would place unpredictable damages to plant running machines. We offer reactive harmonic compensation solution to ensure plant power instability.

Contact Us

Contact Us